Electrical wiring systems, especially copper, typically last 70 to 100 years with proper care, while aluminum wiring may only last 30 to 40 years due to its higher risk of overheating. Outlets, switches, and breakers usually last 15 to 40 years. Faulty installation, harsh conditions, or outdated code compliance can shorten that lifespan and increase fire risks. Regular inspections are essential for safety and catching problems early. Let’s take a closer look at when wiring needs attention and what warning signs to spot.

Key Takeaways

- Copper electrical wiring typically lasts 70 to 100 years with proper installation and maintenance.

- Aluminum wiring has a shorter lifespan, generally 30 to 40 years due to corrosion and overheating risks.

- Circuit breakers and electrical panels last 30 to 40 years but require earlier replacement if frequently tripping.

- Outlets and switches usually need replacement every 15 to 25 years to maintain safe operation.

- Professional inspections every 3 to 5 years help ensure system longevity and identify potential hazards early.

Typical Lifespan of Home Electrical Wiring

When we’re evaluating a home’s electrical wiring, it’s important to know that different wiring systems have varied lifespans—copper wiring generally lasts 70 to 100 years when properly installed and maintained, while aluminum wiring, more common in older homes, lasts just 30 to 40 years due to its higher risk of overheating and corrosion. In our local homes, knob-and-tube wiring—seen pre-1950s—may function but fails modern safety standards, prompting full replacement. Romex (NM) sheathed cable, commonly used since the mid-20th century, shows excellent wire durability, often exceeding 40 years if undisturbed. Homes over 25 years old should have wiring examined by a professional to identify any potential issues early and ensure ongoing safety. Underground feeder (UF) wiring reaches 30+ years but is sensitive to moisture. For our families’ safety and code compliance, electrical upgrades are recommended when aging wiring or visible issues arise, giving us peace of mind and reliability.

Longevity of Common Electrical System Components

Several key electrical components determine the safety and functionality of any wiring system, and each has a distinct service lifespan. For example, circuit breaker longevity typically ranges from 30 to 40 years, but frequent tripping or electrical surges can shorten this period, impacting the system’s reliability and safety. Electrical panels share a similar life expectancy, with aging or outdated models lacking modern code-compliant protection. Outlet replacement frequency falls between 15 and 25 years, although GFCI outlets often need testing and possible replacement around every 10 years to meet current safety standards. Switches usually match outlet lifespan, while capacitors range widely depending on type. Copper or aluminum wiring generally lasts 50 to 70 years or more, making it one of the most durable components in most electrical systems. Regular assessment and timely upgrade of these components help us maintain a safe, code-compliant home for everyone in our community.

Differences Between Wiring Materials

Although all electrical wiring serves the same fundamental purpose—conducting electricity safely—the material composition can significantly affect performance, lifespan, and code compliance. When we choose wiring, copper advantages stand out: high conductivity, excellent flexibility, and resistance to both corrosion and fatigue. This means copper wiring is reliable for both residential and commercial settings and is often favored for critical systems where consistent performance is non-negotiable. On the other hand, aluminum wiring, while lighter and more cost-effective, comes with significant aluminum drawbacks. It is more rigid, prone to oxidation, and generally requires special connectors or coatings to maintain safe conductivity. Aluminum often needs to be upsized to meet code when compared with copper. Considering these factors helps our community make informed, code-compliant, and safe wiring choices. Many modern building codes require ground wires to be included in circuits regardless of whether the wiring is copper or aluminum, emphasizing the importance of grounding for overall system safety.

Factors That Affect Wiring Durability

Selecting the right wiring material is only part of the equation—long-term durability also hinges on a range of environmental, installation, and usage factors. We all want safe, reliable systems, so let’s consider how temperature fluctuations, moisture, pests, and exposure to the elements can accelerate insulation breakdown or corrosion, increasing the environmental impact. Vibration and high-traffic locations add additional stress to electrical components. Installation quality is equally crucial—licensed professionals guarantee code compliance, correct wire gauge, and avoid overcrowded circuits. Overloaded circuits and frequent tripping of breakers can generate excessive heat, shortening lifespan. Regular inspections, meticulous documentation, and prompt upgrades help maintain safety and performance. By carefully managing these factors together, we help guarantee our wiring stands the test of time, keeping homes and businesses connected safely. If ignored, overloading can quickly lead to wire insulation overheating and even electrical fires, making it vital to periodically assess circuit loads and distribute electrical demand wisely.

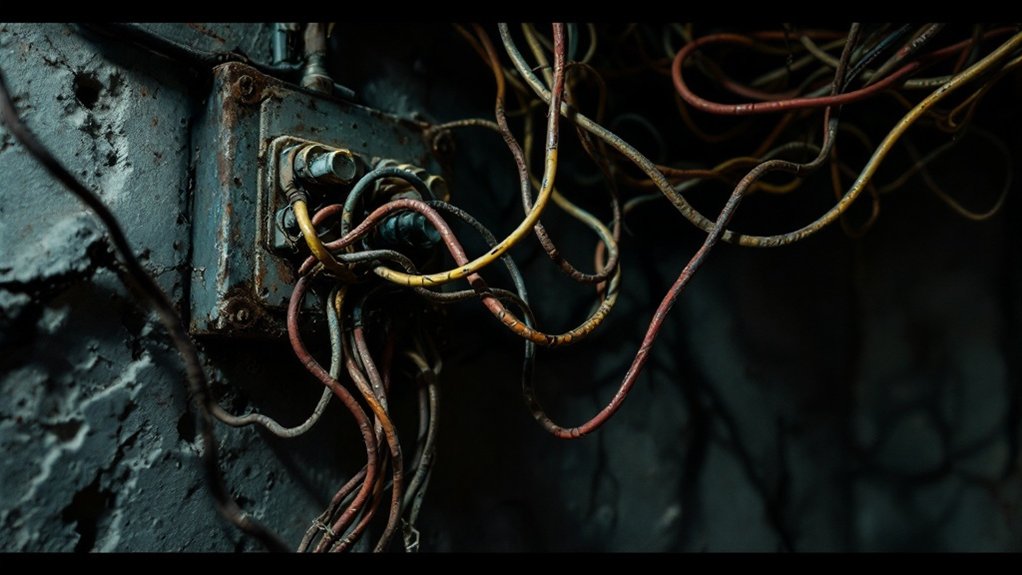

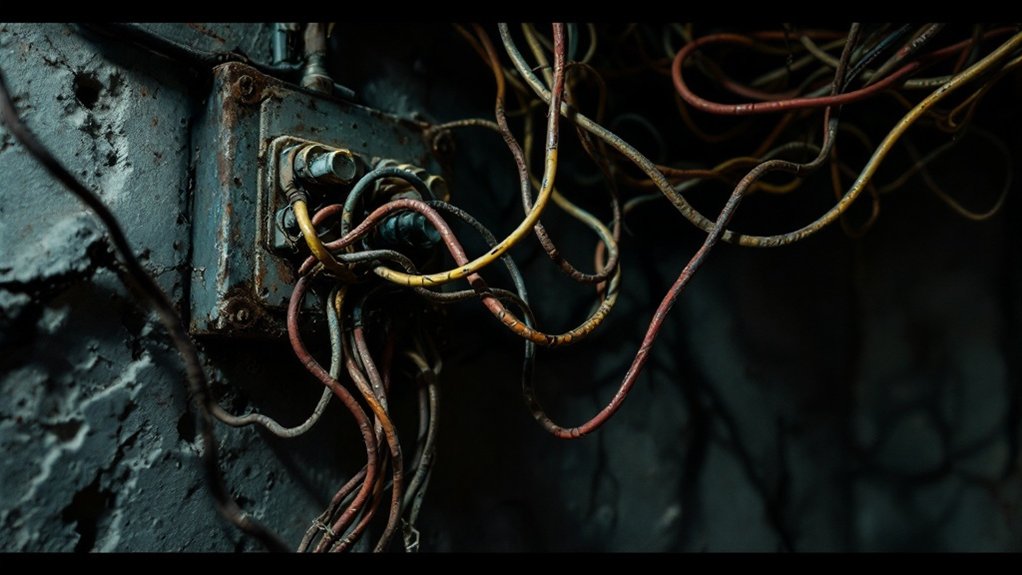

Warning Signs Your Wiring Needs Replacement

How can you tell when your electrical wiring’s no longer safe? As a community committed to safety and code compliance, we need to watch for critical wiring deterioration signs in our homes and businesses. If we see frayed, cracked, or cloth-insulated wires, or discover knob and tube wiring, it’s time for immediate action. Other red flags include warm spots on walls, outlets sparking or arcing, and frequent circuit breaker trips. Flickering or dimming lights, buzzing sounds, burning odors, or hot and discolored outlets also belong on our watchlist. Frequent circuit breaker trips are a common indication that your electrical system may be overloaded or suffering from underlying wiring issues. Aluminum or fabric-insulated wiring, tripping breakers, and repeated repairs highlight major risks. Using these electrical safety tips and recognizing the warning signs helps us protect each other—and our property—from hazardous wiring failures.

Maintenance Tips to Extend Wiring Life

To keep our wiring systems safe and reliable, we need to schedule routine inspections to catch early signs of wear or damage. When we spot any irregularities, it’s essential to address them promptly with the help of a licensed electrician. Staying proactive helps us maintain code compliance and greatly reduces the risk of serious electrical hazards. By being aware of the overall capacity of our electrical system, we can better identify potential issues and prevent overloads.

Schedule Routine Inspections

While it’s easy to overlook, scheduling routine electrical inspections is one of the most effective ways we can extend the lifespan of our wiring and guarantee ongoing safety. Establishing a consistent inspection frequency—typically every three to five years, or sooner if we notice irregularities—helps us spot potential issues before they threaten our property or loved ones. It’s important we rely on licensed professionals whose inspector qualifications meet local code requirements. Qualified electricians thoroughly check for worn insulation, corrosion, loose connections, and defective outlets using the right tools and techniques. Annual electrical inspections recommended by experts not only help maintain efficiency, but also catch small problems before they escalate. They’ll also make certain our panels and grounding systems meet safety codes. By prioritizing these regular checkups as a united community, we protect one another, reduce fire risk, and make certain our electrical systems remain reliable for years to come.

Address Issues Promptly

Acting quickly when electrical issues arise is essential for preserving wiring integrity and ensuring system safety. If we notice signs such as cracks, fraying, or exposed wires during our wiring inspections, it’s vital to act immediately. Conducting a thorough damage assessment helps us identify small problems before they escalate into major hazards. Addressing loose or discolored outlets, and repairing damaged insulation without delay, keeps our wiring compliant with code and minimizes risks of electrical fires. We should never overlook minor defects—prompt repairs prevent deterioration and extend the lifespan of our electrical system. By relying on licensed electricians for any repairs, we maintain the highest safety standards and protect everyone in our home or business. For maximum protection and efficiency, it’s important to schedule regular inspections to catch and address problems early. Quick action is our first line of defense.

Risks of Outdated or Damaged Wiring Systems

When our wiring systems are outdated or damaged, we’re exposed to serious risks like fire hazards and electrical shock, which endanger both our safety and property. These conditions also lead to reduced electrical efficiency, causing frequent outages, power surges, and added stress on our appliances. When homes contain old or damaged insulation, the risk of exposed live wires increases significantly, heightening the danger of accidental fires or electrocution. Let’s examine how failing wiring not only violates code requirements but also compromises the reliability and safety of our home environment.

Fire and Shock Hazards

Because outdated or damaged electrical wiring can’t safely handle today’s energy demands, homes with aging systems are at much higher risk for both fire and electrical shock. We need to recognize that old wiring types, like knob-and-tube or aluminum, often lack the capacity—and safety features—required for modern fire prevention and shock prevention standards. Frayed insulation, improper modifications, and rodent damage each raise the threat of sparks, overheating, or accidental contact with live wires. These hazards can result in severe injuries or even fatalities, especially in kitchens or bathrooms where moisture is present. Routine inspections by professionals can identify potential issues early, helping to prevent fires and electrical shocks before they occur. As a community committed to safety, it’s vital to guarantee our wiring complies with current codes, is properly grounded, and is regularly inspected. Together, we can reduce fire and shock risks in every home.

Reduced Electrical Efficiency

Although many homeowners focus on visible electrical issues, reduced efficiency in outdated or damaged wiring systems can be just as problematic—and costly. When our home’s wiring isn’t up to modern standards, we experience unnecessary energy consumption, higher utility bills, and poor appliance performance. Outdated wiring increases resistance, causing voltage drops that can stress electronics and shorten their lifespan. Dim lights or frequent breaker trips are clear indicators that efficiency is compromised. By considering timely wiring upgrades, we can greatly enhance our energy efficiency, protect our investments, and meet today’s electrical code requirements. As a close-knit community committed to safety and reliability, let’s prioritize modern electrical standards. Upgrading our wiring isn’t just about compliance—it’s about ensuring lasting comfort and efficiency for everyone in our homes. Regular inspections by a licensed electrician can help detect early signs of wear and corrosion, preventing serious hazards and ensuring your wiring continues to operate safely and efficiently.

When to Schedule Electrical Inspections and Upgrades

As electrical systems age or demands on them increase, it’s crucial that we stay proactive with inspections and upgrades to maintain safety and compliance. We recommend following an inspection frequency of every 3 to 5 years for most homes, but if your property is over 50 years old or you’ve recently renovated, it’s smart to schedule sooner. If your home was built before 1985, the wiring may be insufficient for today’s appliances and should be evaluated to ensure it meets modern demands. Key indicators include frequent breaker trips, flickering lights, or damaged outlets. As a community that values safety and code compliance, we should never delay upgrades—especially when wiring nears the 50-70 year mark, or when adding modern appliances that strain old circuits. Upgrade timing is also critical after identifying persistent faults or during major projects. Staying on top of these guidelines helps guarantee every home remains protected and efficient.

Frequently Asked Questions

Can Insurance Cover the Cost of Electrical Rewiring in Older Homes?

When we’re considering electrical rewiring, most insurance policies don’t cover the cost unless damage is due to a covered event. Coverage limits vary, so let’s review your policy together to guarantee your home’s safety and code compliance.

Are There Energy Efficiency Benefits to Upgrading My Home’S Wiring System?

It is understood wiring upgrades deliver real energy savings. By updating to code-compliant systems, we reduce energy loss, support efficient appliances, and improve overall safety. Together, let’s create a safer, more energy-efficient home that benefits everyone in our community.

What Permits Are Needed for a Complete Home Rewiring Project?

For a complete home rewiring project, we’ll need to secure electrical permits from the local building department. This guarantees code compliance and prioritizes home safety, helping us protect your family and property while fostering peace of mind.

How Disruptive Is the Rewiring Process to Daily Household Activities?

When rewiring, we can expect some disruption duration—typically several days—requiring temporary power loss and household adjustments. We’ll work closely with you, ensuring code compliance and safety, while minimizing impact so your family always feels comfortable and informed.

Will Modern Wiring Improve the Resale Value of My Property?

Modern wiring upgrades absolutely boost your property’s appeal, enhancing safety and energy efficiency. When we upgrade wiring to current code compliance, we not only improve safety but also increase market value—making your home more desirable to buyers like us.

Conclusion

When it comes to electrical wiring, we can’t overstate the importance of safety, code compliance, and regular inspections. Wiring lifespans vary, but aging, damage, or outdated materials present serious risks. By staying alert for warning signs and scheduling timely upgrades, we’re protecting our homes, loved ones, and investments. If you suspect your wiring needs attention, don’t hesitate—reach out to professionals like us at Pride Electric to guarantee reliable, code-compliant, and safe electrical systems for years to come.